- Overview

- Quick Detail

- Description

- Applications

- Specifications

- Competitive Advantage

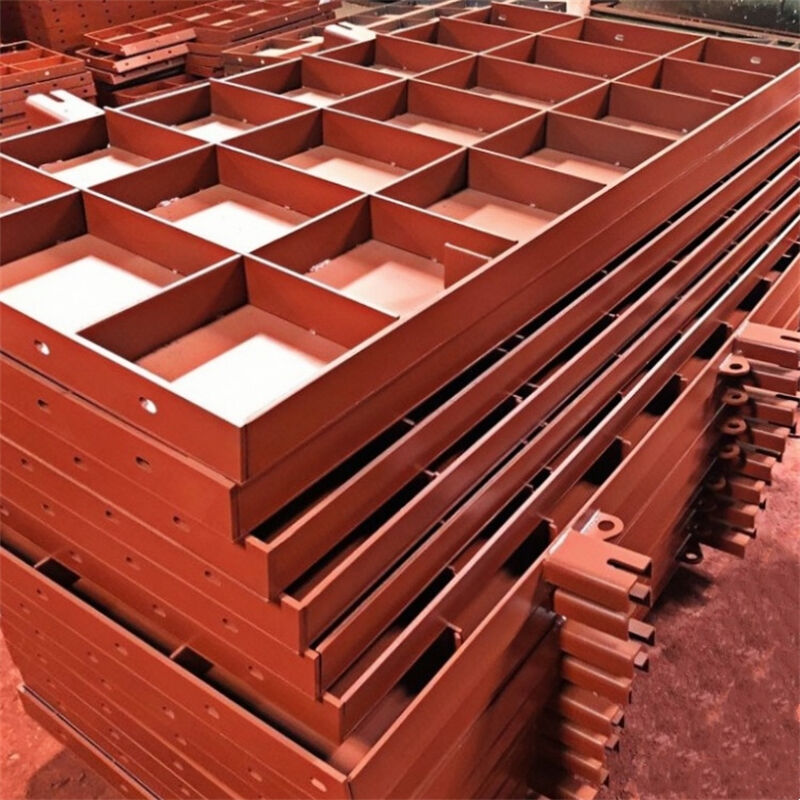

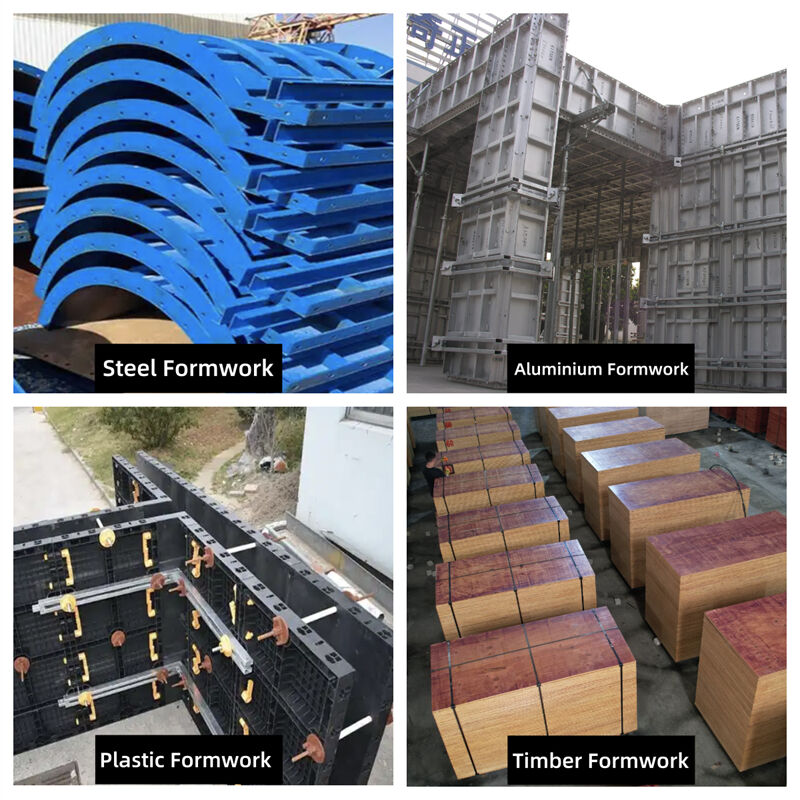

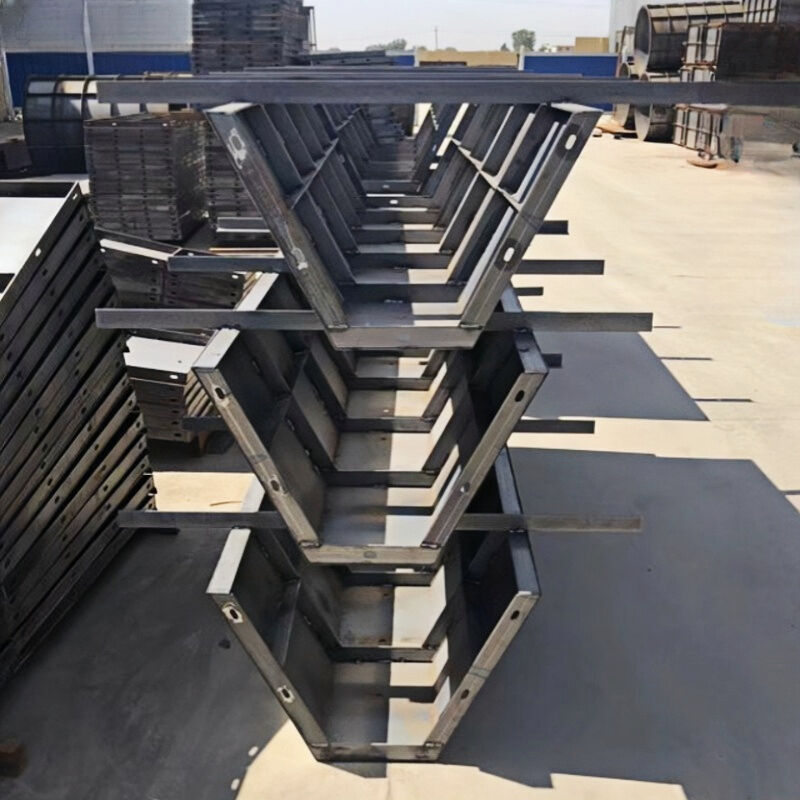

- Related Products

Overview

General product information:

| Place of Origin: | Hebei, China |

| Brand Name: | RFKY |

| Model Number: | |

| Certification: | CE/NFRC/CPR |

Product commercial terms:

| Minimum Order Quantity: | 10 pieces |

| Price: | 15-65 US dollars/piece |

| Packaging Details: | Bundle/Carton/Customizable |

| Delivery Time: | 10-30 days |

| Payment Terms: | T/T ,L/C |

| Supply Ability: | 100000 piece/years |

Quick Detail

Plastic/PVC/PP/ABS concrete Molds

Description

The advantages of plastic formwork are as follows:

Lightweight and Portable

Plastic formwork is extremely lightweight compared to traditional steel or wooden formwork. This characteristic makes it convenient for workers to carry and handle on the construction site, reducing physical exertion during transportation and installation. For instance, when erecting formwork for high-rise buildings, the light weight of plastic formwork allows for easier vertical transportation, saving time and labor.

High Strength and Durability

It has excellent strength and can withstand the pressure and impact during the concrete pouring process without deformation or damage. Moreover, plastic formwork is highly durable, resistant to corrosion, and not affected by factors such as moisture, chemicals, and ultraviolet rays, ensuring its long service life and stable performance even after repeated use.

Smooth Surface and Good Concrete Finish

The surface of plastic formwork is very smooth, which can make the surface of the cast concrete smooth and flat, with few pores and blemishes. This reduces the need for subsequent surface treatment work, such as grinding and plastering, saving both time and materials, and improving the overall quality and appearance of the concrete structure.

Good Flexibility and Customizability

Plastic formwork has good flexibility and can be easily processed and molded into various shapes and sizes according to specific project requirements. It can be customized to meet the formwork needs of different building structures, such as curved surfaces, irregular shapes, and complex geometries, providing great convenience for the construction of unique architectural designs.

Environmentally Friendly and Recyclable

Being made from recyclable materials, plastic formwork is an environmentally friendly option. After its useful life, it can be recycled and reused, reducing waste and environmental pollution. In contrast to some traditional formwork materials that may cause more waste and have a higher environmental impact, plastic formwork is more in line with the concept of sustainable development.

Cost-Effective in the Long Run

Although the initial cost of plastic formwork may be relatively high, considering its long service life, high reusability, and the savings in labor and material costs during the construction process, it proves to be cost-effective in the long term. The reduced need for frequent formwork replacement and the lower consumption of auxiliary materials contribute to overall cost savings.

Fire and Electrical Safety

Plastic formwork is non-combustible and non-conductive, which significantly reduces the risk of fire and electrical shock accidents on the construction site. This enhances the safety of the construction environment, providing a safer working condition for construction workers and reducing potential safety hazards.

Applications

For Walls Column

For Concrete casting

For Wall, Slab, Columns

For Building Project

For Concrete Pillars

For Construction

For column and wall

For Building metal mold

For Construction House Column Wall Slab

For Building Project

For curvy curve curved concrete work

For Building Construction Modular House

Specifications

| 7.8cm Thickness PLASTIC FORMWORK | |||||||||

| Type | NO. | Length(cm) | Width(cm) | Thickness(cm) | |||||

| Adjustmentboard | 1 | 20 | 15 | 7.8 | Standard board | 24 | 150 | 15 | 7.8 |

| 2 | 20 | 20 | 7.8 | 24 | 150 | 20 | 7.8 | ||

| 3 | 30 | 30 | 7.8 | 25 | 150 | 25 | 7.8 | ||

| 4 | 30 | 20 | 7.8 | 26 | 150 | 30 | 7.8 | ||

| 5 | 30 | 15 | 7.8 | 27 | 150 | 35 | 7.8 | ||

| 6 | 40 | 40 | 7.8 | 28 | 150 | 40 | 7.8 | ||

| 7 | 40 | 30 | 7.8 | 29 | 150 | 45 | 7.8 | ||

| 8 | 40 | 20 | 7.8 | 30 | 150 | 50 | 7.8 | ||

| 9 | 40 | 15 | 7.8 | 31 | 150 | 60 | 7.8 | ||

| 10 | 50 | 50 | 7.8 | 32 | 150 | 70 | 7.8 | ||

| 11 | 50 | 45 | 7.8 | 33 | 150 | 80 | 7.8 | ||

| 12 | 50 | 40 | 7.8 | 34 | 150 | 90 | 7.8 | ||

| 13 | 50 | 30 | 7.8 | 35 | 150 | 100 | 7.8 | ||

| 14 | 50 | 20 | 7.8 | 36 | 150 | 120 | 7.8 | ||

| 15 | 50 | 15 | 7.8 | Outer cormer | 37 | 150 | 33 | 7.8 | |

| 16 | 60 | 60 | 7.8 | Inner comner | 38 | 150 | 30 | 10 | |

| 17 | 60 | 50 | 7.8 | Camfer | 39 | 75 | 35 | 35 | |

| 18 | 60 | 45 | 7.8 | 40 | 75 | 30 | 30 | ||

| 19 | 60 | 40 | 7.8 | 41 | 75 | 25 | 25 | ||

| 20 | 60 | 30 | 7.8 | 42 | 75 | 20 | 20 | ||

| 21 | 60 | 20 | 7.8 | 43 | 75 | 15 | 15 | ||

| 22 | 60 | 15 | 7.8 | 44 | 75 | 10 | 10 | ||

| Type | NO. | Length(cm) | Width(cm) | Thickness(cm) |

| Standard board | 1 | 120 | 20 | 6.5 |

| 2 | 120 | 30 | 6.5 | |

| 3 | 120 | 35 | 6.5 | |

| 4 | 120 | 40 | 6.5 | |

| 5 | 120 | 45 | 6.5 | |

| 6 | 120 | 50 | 6.5 | |

| 7 | 120 | 60 | 6.5 |

| Connect the handle | |

| NO. | Specification |

| 1 | 2cm |

| 2 | 4.3cm |

| 3 | 5cm |

| 4 | 8cm |

| 5 | 9cm |

Competitive Advantage

We have advanced manufacturing technology and strict quality inspection process.We have Universal testing machine、Multi-functional salt spray testing machine、Multi-purpose spectrometer,We guarantee that every product has qualified quality.