- Conspectus

- Velox Detail

- Descriptio

- Applications

- Specifications

- Aliquam commodo

- Producta Relata

Conspectus

Informatio generalis de producto:

| Locus Originis: | Hebei, China |

| Nomen Notae: | RFKY |

| Numerus Moduli: | |

| Certificatio: | cE |

Clausulae commerciales producti:

| Quantitas Ordinis Minimae: | 10 Pieces |

| Pretium: | 8-20 denarios americanos/pars |

| Packaging Details: | Fasciculus/Carton/Personalizabile |

| Tempus traditionis: | 10-30 dies |

| Termini solucionis: | T/T ,L/C |

| Capacitas Supplicandi: | 50000 tons/annos |

Velox Detail

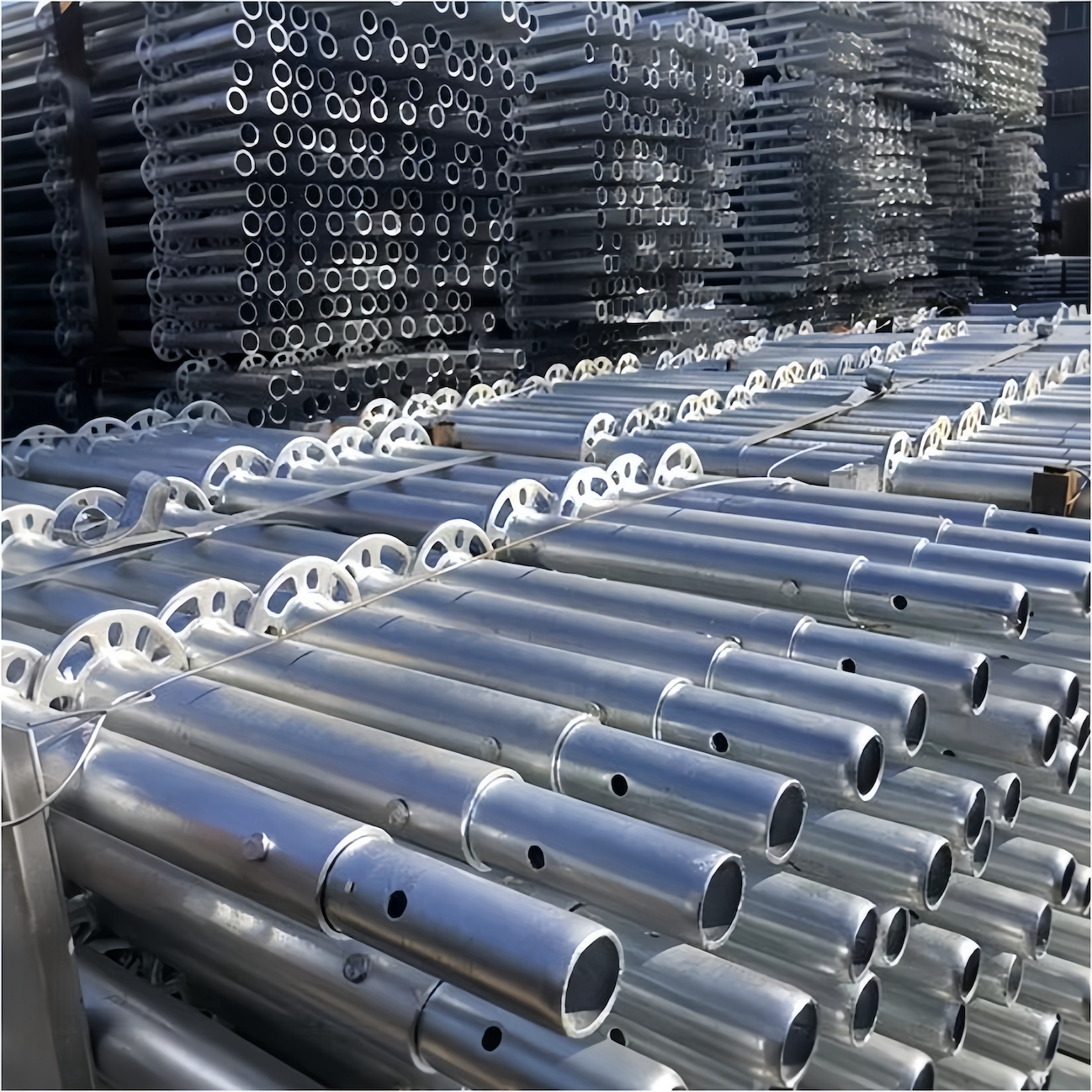

·Layher Scaffolding/impalcatura/Andamio/Echafaudage

·Ringlock Scaffolding/impalcatura/Andamio/Echafaudage

·Scena scaffold

Descriptio

Vantagii Disc Scaffolding

Stabilitas Structurae

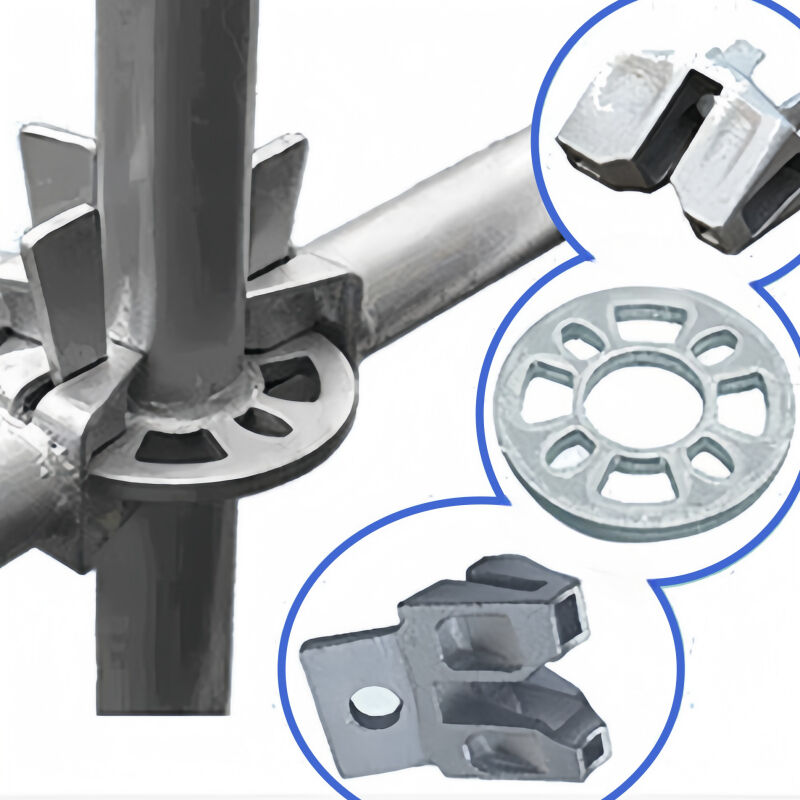

Discus scaffold conficitur ex fortibus ferreis tubulis et unicum discum articulationibus. Articulationes habent fiduciam serationem, quae verticalia stipites et horizontalia vectigalia firma coniungere potest, formans stabilem structuram tridimensionalem. Haec stabilis structura efficaciter resistere varia externa vires potest, ut ventus onus, vibratio, et impactus, minuendo periculum scaffold collapsus et conservando operariorum tecturarum securitatem.

Facilis Coniunctio et Disiunctio

Componentes discus scaffold simplices sunt et standardizati, et methodus connexionis intuitiva est et facile operari. Operarii tantummodo horizontalia vectigalia et obliqua sustentacula in correspondentibus discum articulationibus inserere et eos cum speciali clavis adstringere debent ut completionem assembly faciant. Etiam processus dissectionis valde simplex est, quod multum temporis et laboris sumptus parvificat et constructionis efficientiam meliorat.

Aequabiliter et Versatilis

Cavum discum bonam habet adjustabilitatem. Poles verticales per connectionem manici altitudine adjustari possunt, et bars horizontales et braces diagonales etiam secundum reales necessitates loci constructionis adjustari possunt, ut varias magnitudines et formas structurarum scaffold forment. Haec versatilitas eam aptam facit pro variis projectis constructionis, sive sit aedificium excelsius, pons, aut fabbrica industrialis, omnibus necessitatibus loci constructionis satisfacere potest.

Magna Capacitas Ferendi Onus

Gratias altissimis materialibus et designo scientifico, cavum discum summam habet vim portandi onera. Onus grave portare potest, sicut materiales constructionis, apparatus, et magna multitudo operariorum, solidum subsidium operationi constructionis praebens. In quibusdam projectis constructionis magnis, cavum discum progressum normalem projecti etiam in conditionibus gravium onerum conservare potest.

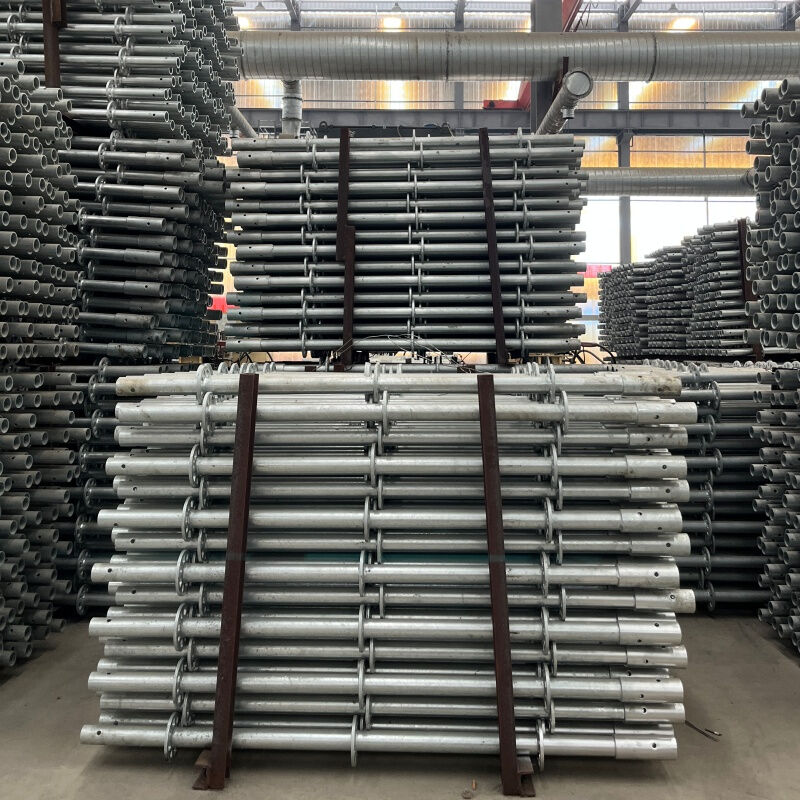

Durabilitas et Longitudo

Superficies disci scaffold solita tractatur cum mensuris anti-corrosionis et anti-rugosis, sicut galvanizatio immersa vel pulverisatio. Hoc tractamentum potest efficaciter prohibere scaffold a corruptione per ambientes externos, sicut imber, nix et humiditas, et prolongare eius vitam usui. Praeterea, materiales altae fortitudinis usi in scaffold etiam certificant eius durabilitatem et possunt sustinere usum longo tempore et repetitam costructionem et dissectionem.

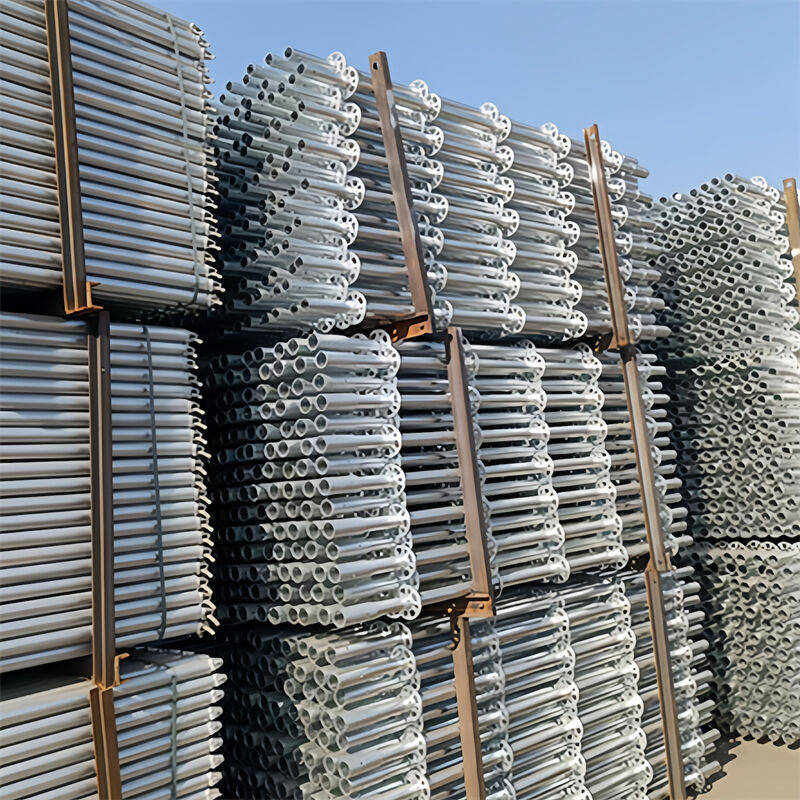

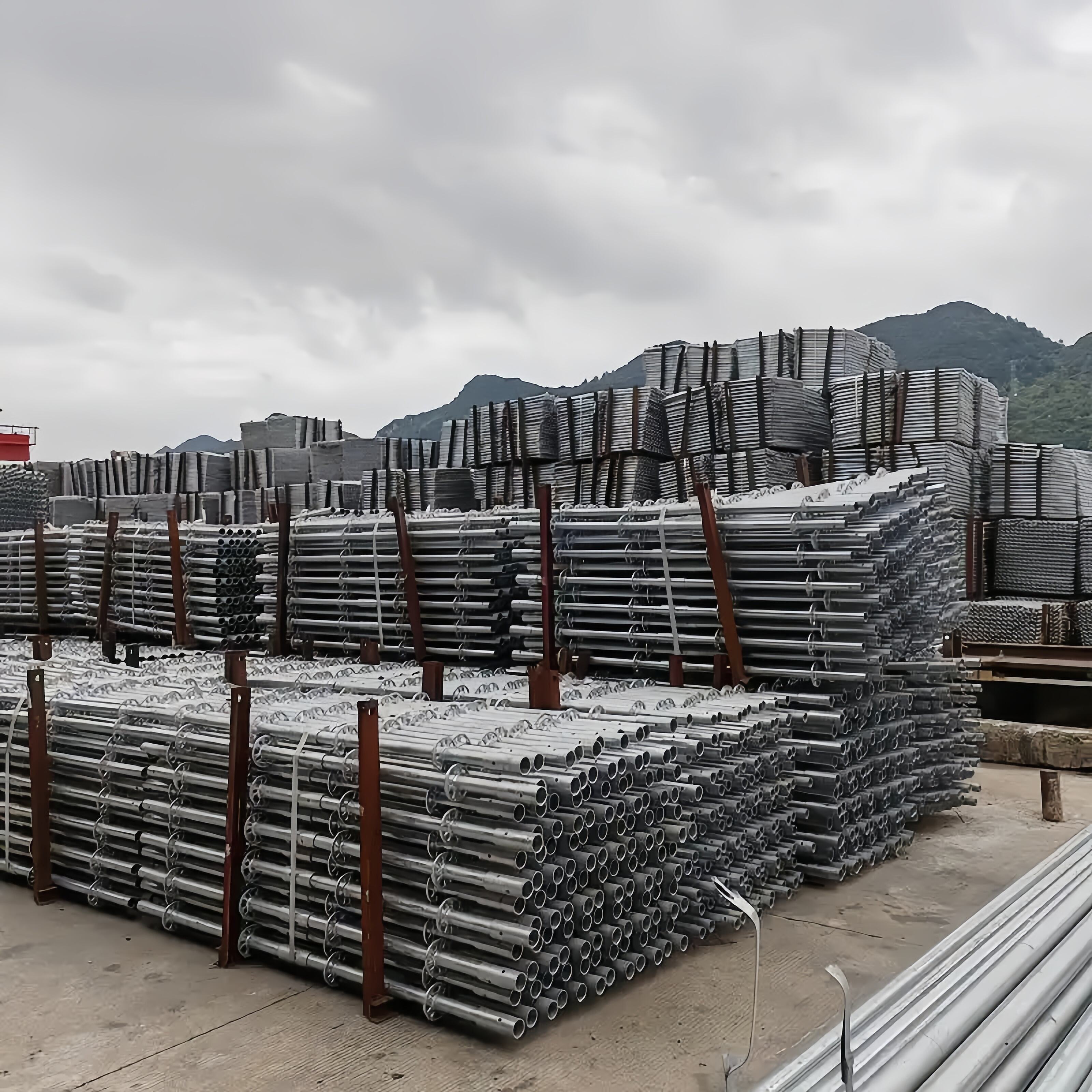

Spatio Parcendo

Cum scaffold discus non est in usu, eius componentes possunt dissolvi et ordinari neate, occupantes valde parvum spatium stoccaggio. Comparatum cum aliquot scaffold traditionalibus, habet manifestas praerogativas in utilisatione spatii. Hoc est valde utile pro locis constructionis cum limitato spatio, quod potest salvare pretiosum spatium loci et meliorare efficientiam administrationis loci.

Salus et Conformitas

Scafo discii consonat normis et regulationibus pertinentibus ad tutelam nationali et internationali. In cursu designandi et fabricandi, rigorose controlantur qualitas et probantur tutela ut certus sit quod unusquisque componentis satisfaciat requisitis tutele. Praeterea, scafoides potest etiam instrui serie accessariorum tutele, sicut balustradae, tabulae pedales, et retia tutele, ut amplius meliorem tutelem conditionis constructionis et tueatur salutem operariorum.

Pulchritudo Visu

Apparitio scafoidis discii est relativiter simplex et nitida, cum sensu quodam aesthetico. Comparata cum aliquibus structuris scafoidum traditionalium et complexiorum, potest dare hominibus experimentum visuale commodius. In quibusdam projectis constructionis urbanae vel projectis cum altioribus requisitis aestheticis, scafoides discii potest melius integrari in ambientem circumstantem et minuere impactum visibilem super prospectum urbis.

Applications

Ad Opus Lateritium

Ad Aedificia Constructiva

Ad Constructionem Aedificiorum Altiorum

ad applicationem concreti aedificii

ad conservationem aedificiorum altorum

Ad Opus Lateritium

Pro Fabrica

Pro schola

Specifications

| Standards | |||||

| Diameter Tubuli (mm) | Crassitudo Tubuli (mm) | Materia | Pondus(kg) | Longitudo(mm) | Superficies curatio |

| 48 | 3/3.25 | Q3558 | 1.71 | 200 | PulvereCoctus/HDG/Tinctus |

| 48 | 3/3.25 | Q3558 | 3.5 | 500 | PulvisCoactus/HDG/Tinctus |

| 48 | 3/3.25 | Q355B | 5.8 | 1000 | PulvisCoactus/HDG/Tinctus |

| 48 | 3/3.25 | Q355B | 8.1 | 1500 | PulvisCoactus/HDG/Tinctus |

| 48 | 3/3.25 | Q355B | 10.5 | 2000 | PulvisCoactus/HDO/Tinctus |

| 48 | 3/3.25 | Q355B | 12.9 | 2500 | PulvisCoactus/HDO/Tinctus |

| 48 | 3/3.25 | Q355B | 15.1 | 3000 | PulvereCoctus/HDG/Tinctus |

| Lactea | |||||

| Diameter Tubuli (mm) | Crassitudo Tubuli (mm) | Materia | Pondus(KO) | Longitudo(mm) | Superficies curatio |

| 48 | 3/2.75 | Q235B | 2.29 | 600 | PulvereCoctus/HDG/Tinctus |

| 48 | 3/2.75 | Q235B | 3.3 | 900 | PulvereCoctus/HDG/Tinctus |

| 48 | 3/2.75 | Q235B | 4.25 | 1200 | PulvereCoctus/HDG/Tinctus |

| 48 | 3/2.75 | Q235B | 5.25 | 1500 | PulvereCoctus/HDG/Tinctus |

| 48 | 3/2.75 | Q235B | 6.19 | 1800 | PulvereCoctus/HDG/Tinctus |

| Diagonales Baltei | |||||

| Diameter Tubuli (mm) | Crassitudo Tubuli (mm) | Materia | Pondus(kg) | Longitudo(mm) | Superficies curatio |

| 42 | 3/2.75 | Q195 | 6.44 | 2045 | PulvisCoactusHDG/Tinctus |

| 42 | 3/2.75 | Q195 | 5.3 | 1610 | PulvisCoactusHDG/Tinctus |

| 42 | 3/2.75 | Q195 | 5.57 | 1710 | PulvisCoactusHDG/Tinctus |

| 42 | 3/2.75 | Q195 | 5.95 | 1860 | PulvisCoactusHDG/Tinctus |

| 42 | 3/2.75 | Q195 | 7.54 | 2442 | PulvisCoactusHDG/Tinctus |

| 42 | 3/2.75 | Q195 | 6.75 | 2172 | PulvisCoactusHDG/Tinctus |

| 42 | 3/2.75 | Q195 | 7.3 | 2291 | PulvisCoactusHDG/Tinctus |

| 42 | 3/2.75 | Q195 | 8.2 | 2619 | PulvisCoactusHDG/Tinctus |

Aliquam commodo

Habemus technologiam manufacturam progressivam et processum inspectionis qualitatis strictum. Possidemus machinam probandi universalem, machinam probandi nebulam multiformem, et spectrometrum multiplex. Confirmamus quod qualitas omnis producti sit approbata.