Lightweight ABS PP PVC Forming Shuttering Wall Panel Column Slab Panel Reusable Plastic Concrete Formwork

- Overview

- Quick Detail

- Description

- Applications

- Specifications

- Competitive Advantage

- Related Products

Overview

General product information:

| Place of Origin: | Hebei, China |

| Brand Name: | RFKY |

| Model Number: | |

| Certification: | CE/NFRC/CPR |

Product commercial terms:

| Minimum Order Quantity: | 10 pieces |

| Price: | 40-65 US dollars/piece |

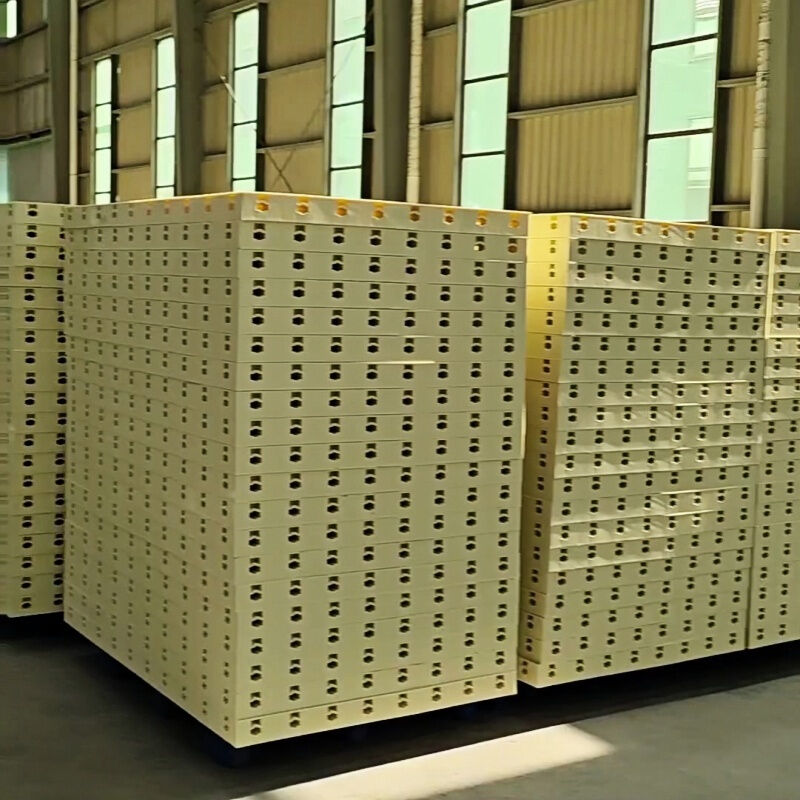

| Packaging Details: | Bundle/Carton/Customizable |

| Delivery Time: | 10-30 days |

| Payment Terms: | T/T ,L/C |

| Supply Ability: | 100000 piece/years |

Quick Detail

Plastic/PVC/PP/ABS concrete Molds

Description

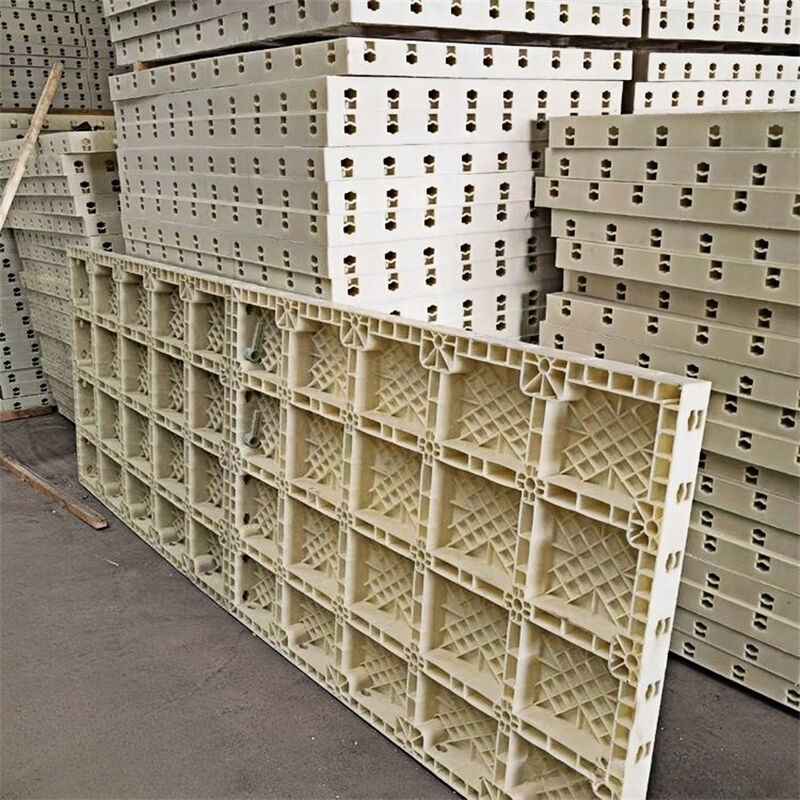

Plastic formwork is a new type of building formwork. Compared with traditional wooden formwork and steel formwork, it has the following advantages:

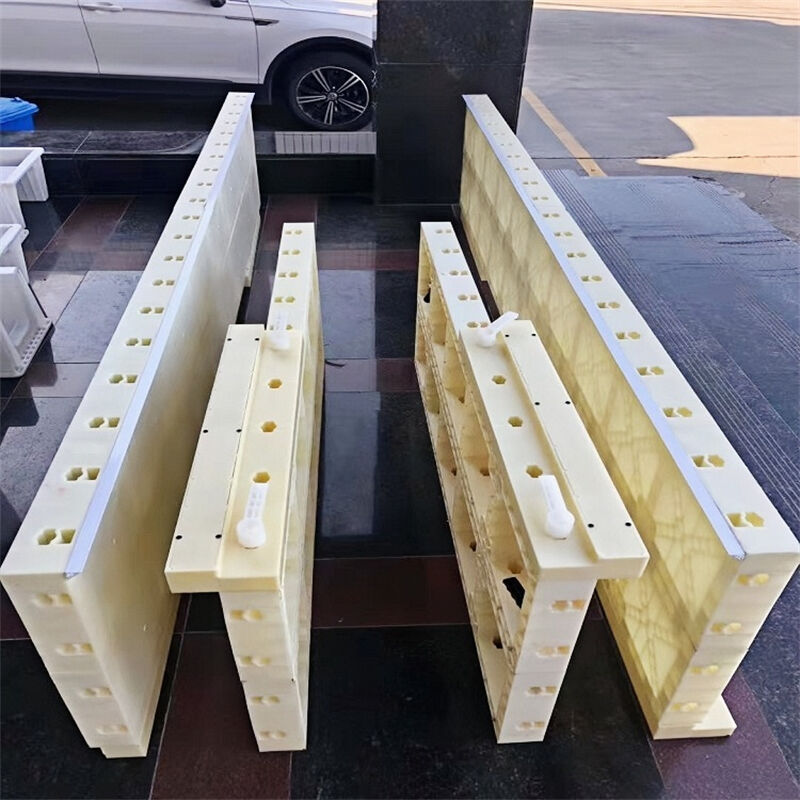

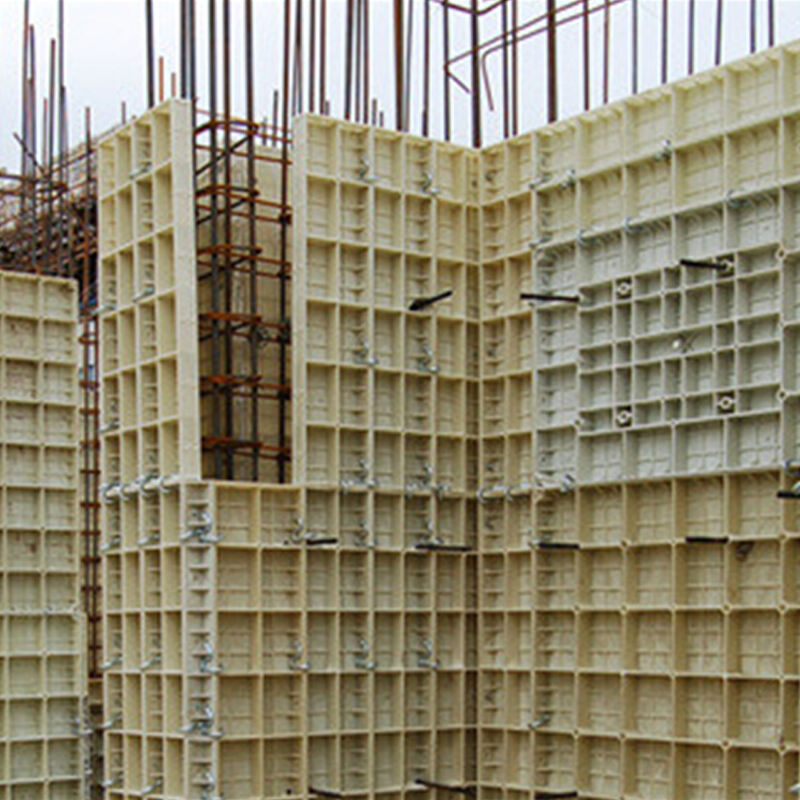

Lightweight and Easy to Handle

Plastic formwork is significantly lighter than steel formwork, making it easier for workers to carry, install, and dismantle on the construction site, reducing labor intensity and improving construction efficiency.

For example, when constructing a multi-story building, the lightweight nature of plastic formwork allows workers to quickly transport it to different floors, facilitating the rapid progress of the project.

High Durability and Reusability

Plastic formwork has good corrosion resistance and is not affected by moisture, rust, or rot like wood and steel. It can maintain its performance and shape after multiple uses, with a service life of up to 30 to 50 times.

In a large-scale construction project, the reusable plastic formwork can significantly reduce the consumption of formwork materials and save costs.

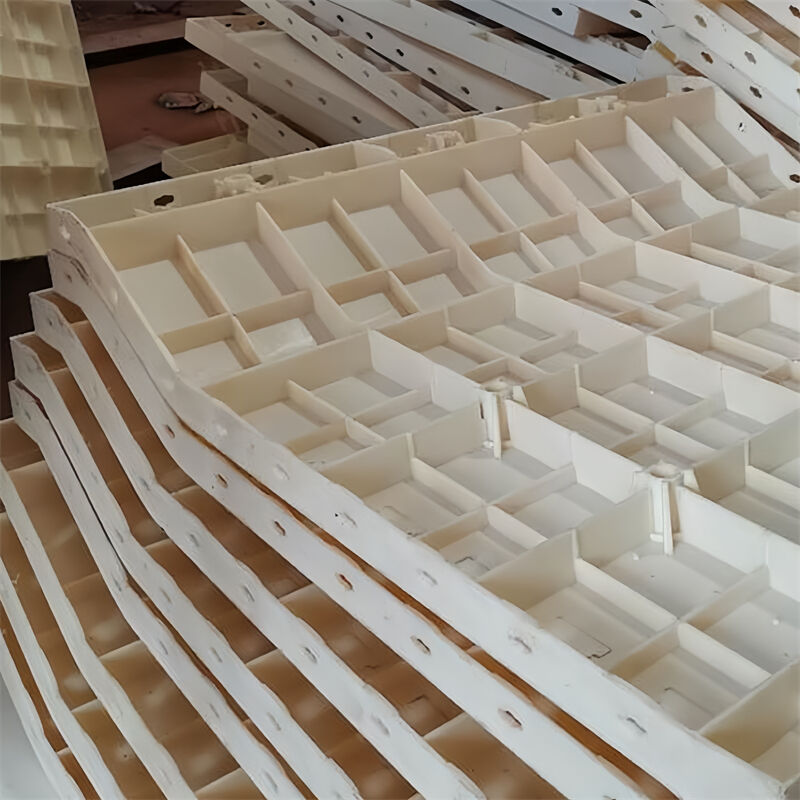

Good Surface Quality of Concrete

The surface of plastic formwork is smooth, which can make the surface of the cast concrete smooth and flat, reducing the need for subsequent surface treatment and saving plastering materials and labor costs.

In the construction of some decorative concrete structures, such as fair-faced concrete walls, the use of plastic formwork can directly achieve a good decorative effect.

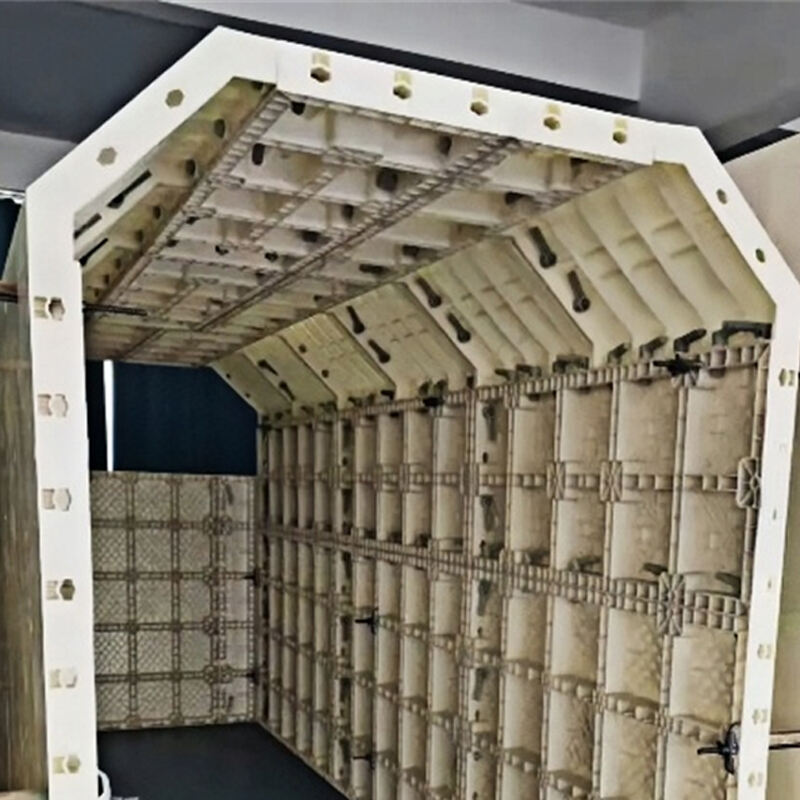

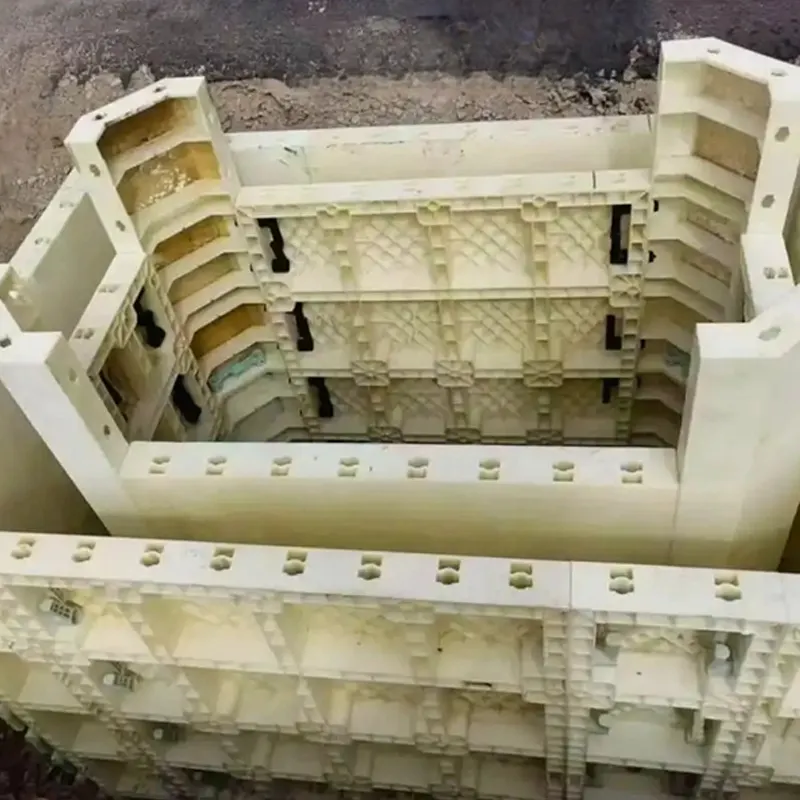

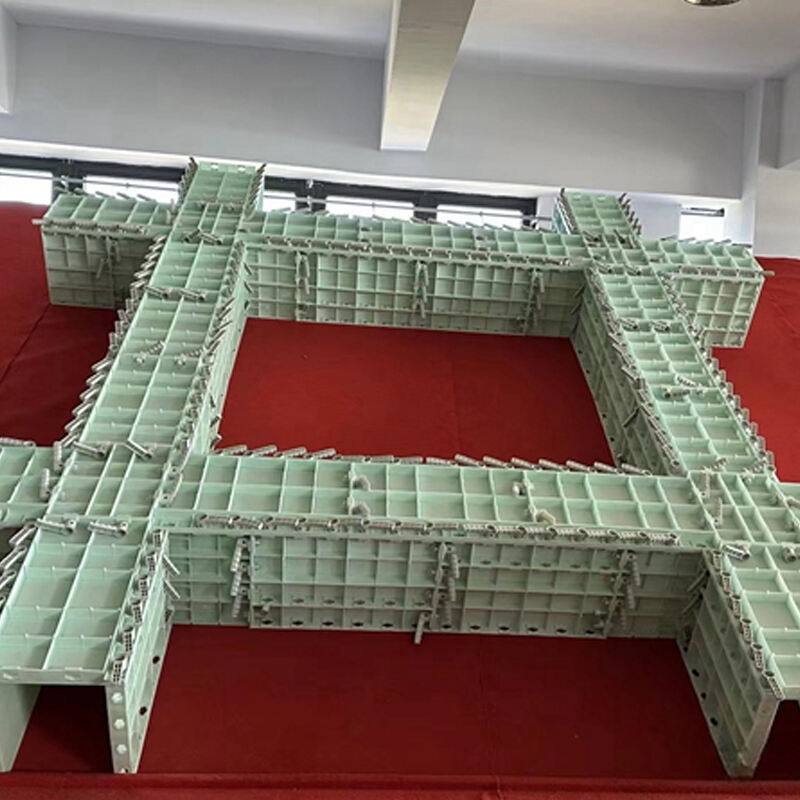

Excellent Formability and Versatility

Plastic formwork has good plasticity and can be made into various shapes and sizes according to the needs of the project to meet the formwork requirements of different building structures, such as curved surfaces, arches, and special-shaped components.

In the construction of some unconventional architectural designs, such as art museums and stadiums with special shapes, plastic formwork can play a unique role.

Environmental Protection and Energy Saving

Plastic formwork is made of recyclable materials, which is in line with the concept of environmental protection and sustainable development. After the end of its service life, it can be recycled and reused to reduce environmental pollution.

Compared with traditional formwork materials, the production process of plastic formwork consumes less energy and emits less greenhouse gases, contributing to energy conservation and emission reduction in the construction industry.

Cost-Effectiveness

Although the initial purchase cost of plastic formwork may be slightly higher than that of some traditional formwork materials, considering its long service life, reusability, and the reduction of labor and material costs during the construction process, the overall cost is more economical in the long run.

In a large number of repeated use scenarios, the economic advantages of plastic formwork will be more obvious.

Safety

Plastic formwork is non-conductive and non-combustible, reducing the risk of fire and electric shock accidents on the construction site, and improving the safety of the construction environment.

In some construction sites with high safety requirements, such as petrochemical plants and power plants, the use of plastic formwork can provide more reliable safety protection.

Applications

For Walls Column

For Concrete casting

For Wall, Slab, Columns

For Building Project

For Concrete Pillars

For Construction

For column and wall

For Building metal mold

For Construction House Column Wall Slab

For Building Project

For curvy curve curved concrete work

For Building Construction Modular House

Specifications

| 7.8cm Thickness PLASTIC FORMWORK | |||||||||

| Type | NO. | Length(cm) | Width(cm) | Thickness(cm) | |||||

| Adjustmentboard | 1 | 20 | 15 | 7.8 | Standard board | 24 | 150 | 15 | 7.8 |

| 2 | 20 | 20 | 7.8 | 24 | 150 | 20 | 7.8 | ||

| 3 | 30 | 30 | 7.8 | 25 | 150 | 25 | 7.8 | ||

| 4 | 30 | 20 | 7.8 | 26 | 150 | 30 | 7.8 | ||

| 5 | 30 | 15 | 7.8 | 27 | 150 | 35 | 7.8 | ||

| 6 | 40 | 40 | 7.8 | 28 | 150 | 40 | 7.8 | ||

| 7 | 40 | 30 | 7.8 | 29 | 150 | 45 | 7.8 | ||

| 8 | 40 | 20 | 7.8 | 30 | 150 | 50 | 7.8 | ||

| 9 | 40 | 15 | 7.8 | 31 | 150 | 60 | 7.8 | ||

| 10 | 50 | 50 | 7.8 | 32 | 150 | 70 | 7.8 | ||

| 11 | 50 | 45 | 7.8 | 33 | 150 | 80 | 7.8 | ||

| 12 | 50 | 40 | 7.8 | 34 | 150 | 90 | 7.8 | ||

| 13 | 50 | 30 | 7.8 | 35 | 150 | 100 | 7.8 | ||

| 14 | 50 | 20 | 7.8 | 36 | 150 | 120 | 7.8 | ||

| 15 | 50 | 15 | 7.8 | Outer cormer | 37 | 150 | 33 | 7.8 | |

| 16 | 60 | 60 | 7.8 | Inner comner | 38 | 150 | 30 | 10 | |

| 17 | 60 | 50 | 7.8 | Camfer | 39 | 75 | 35 | 35 | |

| 18 | 60 | 45 | 7.8 | 40 | 75 | 30 | 30 | ||

| 19 | 60 | 40 | 7.8 | 41 | 75 | 25 | 25 | ||

| 20 | 60 | 30 | 7.8 | 42 | 75 | 20 | 20 | ||

| 21 | 60 | 20 | 7.8 | 43 | 75 | 15 | 15 | ||

| 22 | 60 | 15 | 7.8 | 44 | 75 | 10 | 10 | ||

| Type | NO. | Length(cm) | Width(cm) | Thickness(cm) |

| Standard board | 1 | 120 | 20 | 6.5 |

| 2 | 120 | 30 | 6.5 | |

| 3 | 120 | 35 | 6.5 | |

| 4 | 120 | 40 | 6.5 | |

| 5 | 120 | 45 | 6.5 | |

| 6 | 120 | 50 | 6.5 | |

| 7 | 120 | 60 | 6.5 |

| Connect the handle | |

| NO. | Specification |

| 1 | 2cm |

| 2 | 4.3cm |

| 3 | 5cm |

| 4 | 8cm |

| 5 | 9cm |

Competitive Advantage

We have advanced manufacturing technology and strict quality inspection process.We have Universal testing machine、Multi-functional salt spray testing machine、Multi-purpose spectrometer,We guarantee that every product has qualified quality.